About Us

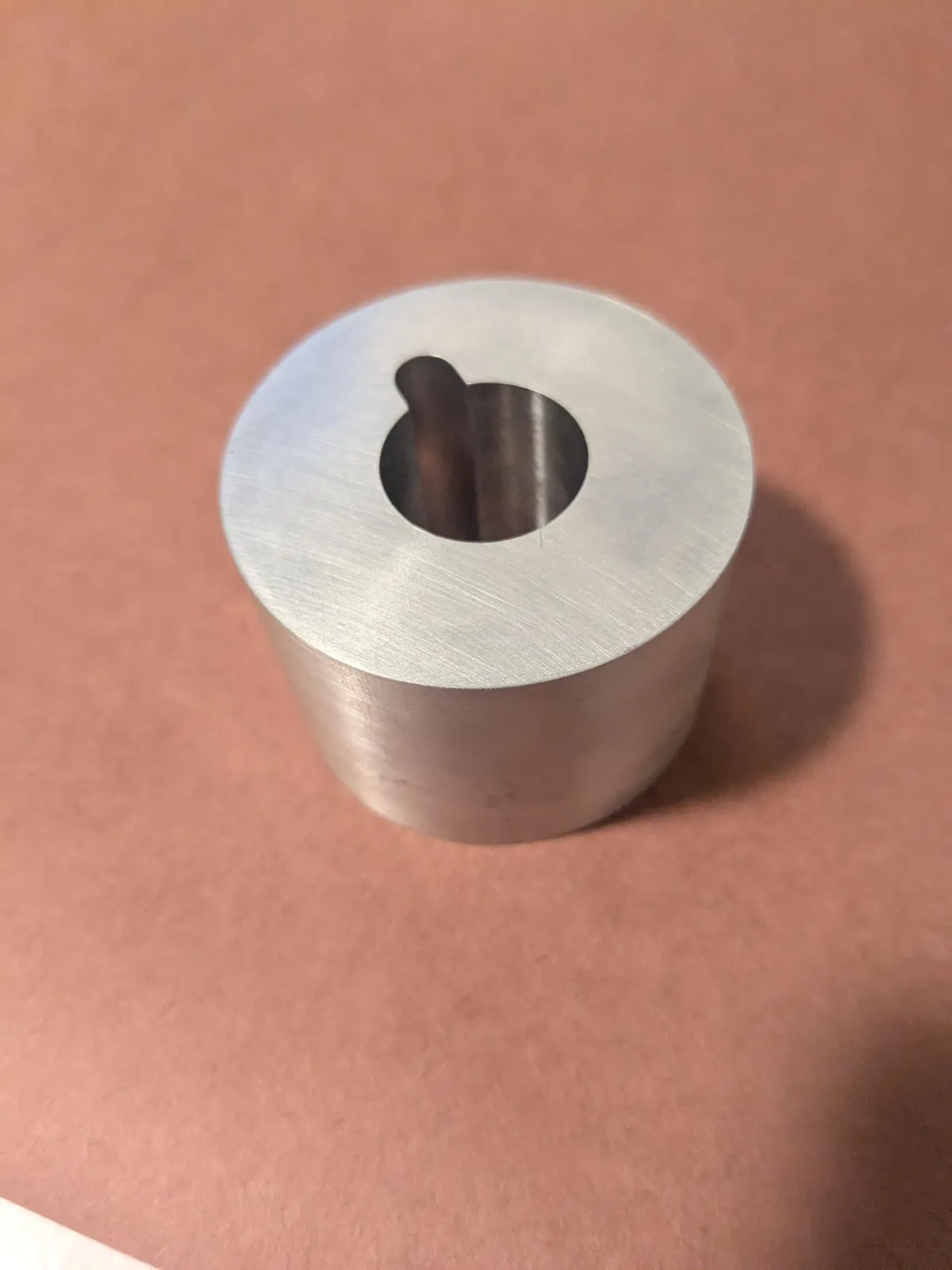

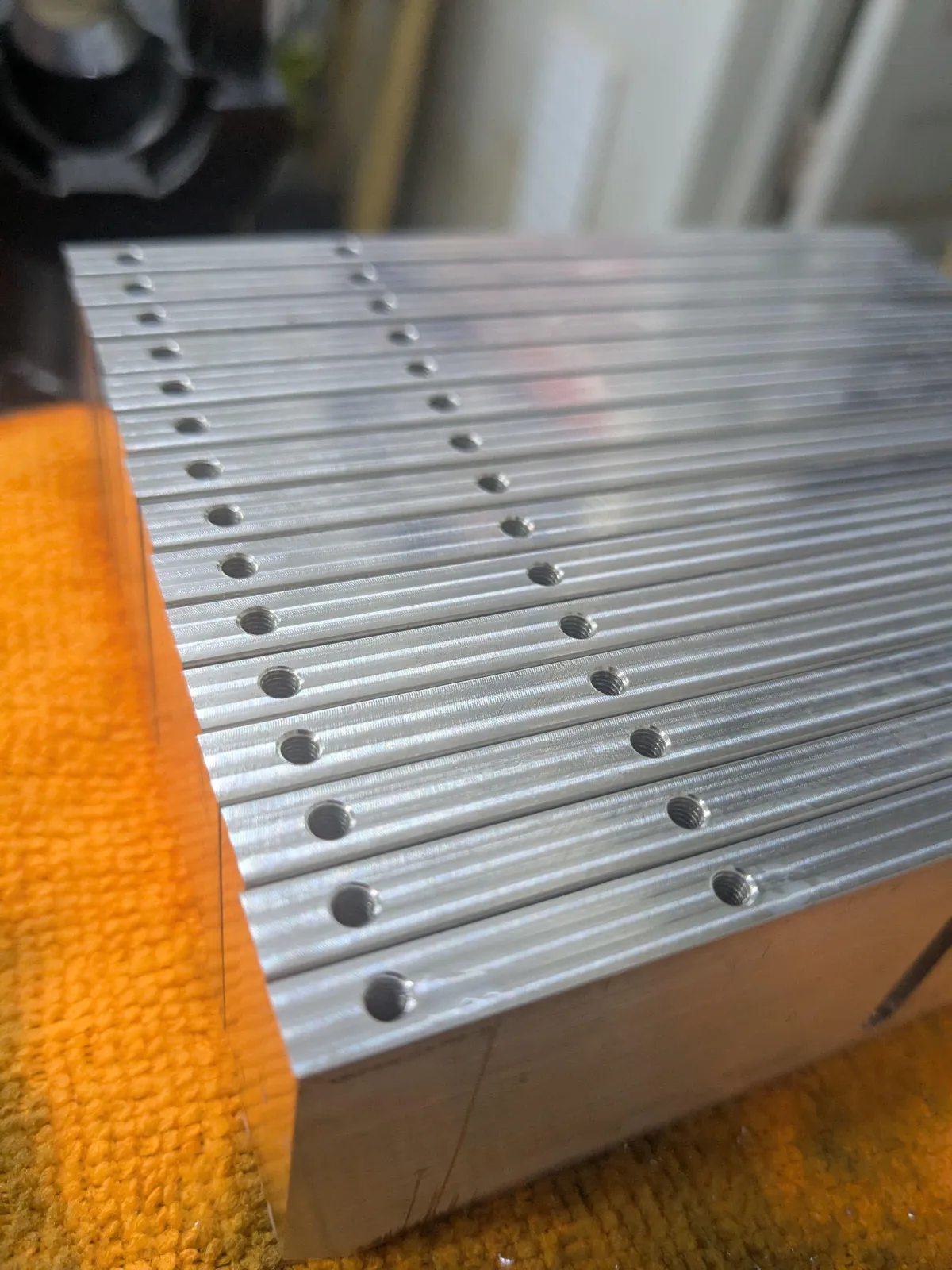

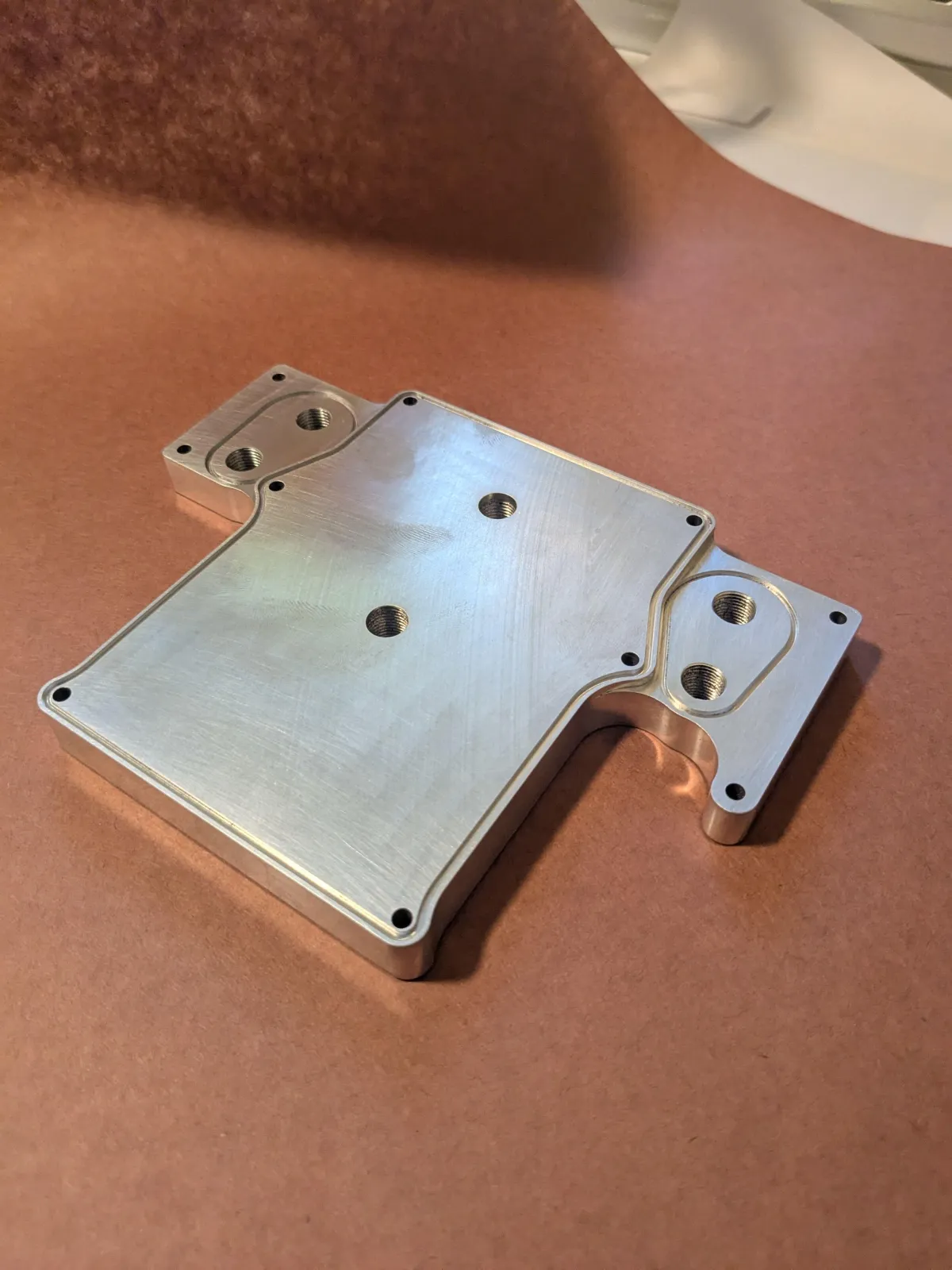

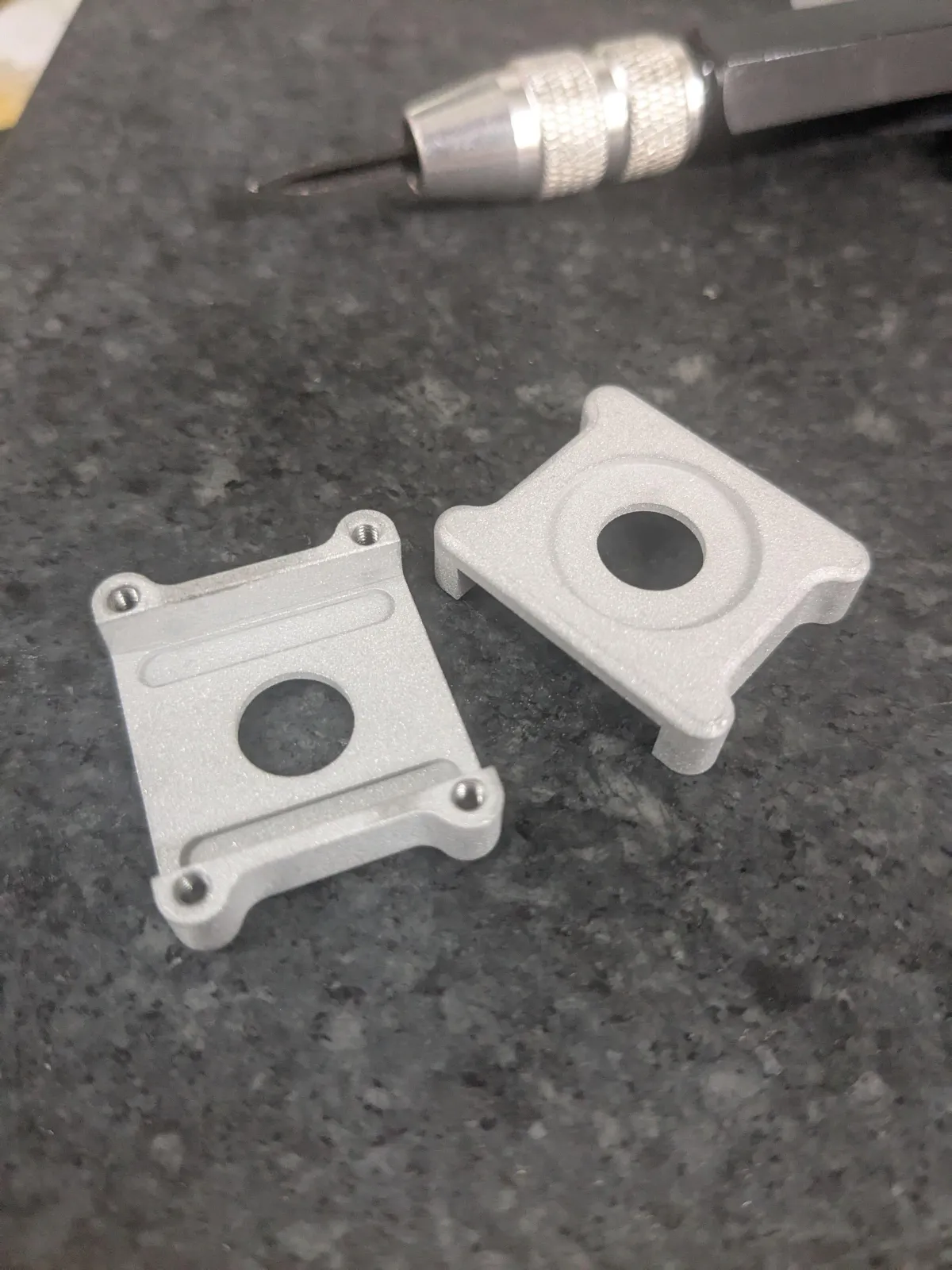

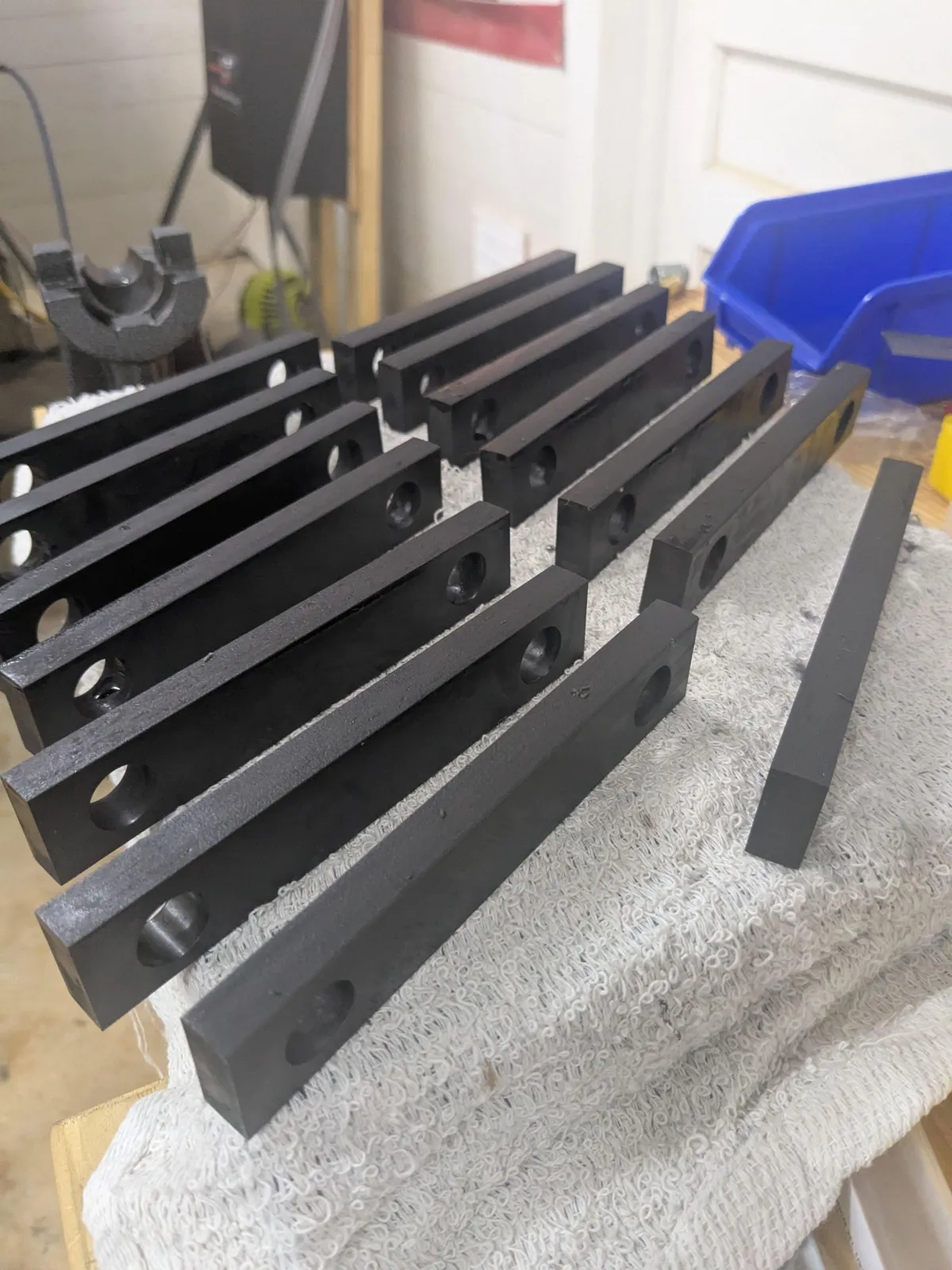

Prickly Pear Prototypes is a precision CNC machine shop in Luling, Texas, building tight-tolerance prototypes and small-to-medium production runs for industries that demand accuracy and speed. Our expertise spans high-performance metals and engineered materials, supported by a commitment to clear communication and reliable delivery.

Since 2021, we’ve worked with teams in medical, energy, and advanced hardware, producing components where quality and consistency matter most. We regularly work under strict NDAs, protecting customer intellectual property and confidentiality from start to finish.

Whether you need a single prototype or scalable production components, we deliver the same level of care, precision, and trust on every part.

Certified Inspection & Compliance Standards

✅ Geometric Dimensioning & Tolerancing (GD&T):

Full GD&T capability, including flatness, concentricity, and more

Functional gaging with custom fixtures to verify complex callouts

Per-print compliance to ensure every part meets exact specs

✅ Trusted for Precision & Compliance:

10+ years of experience machining tight-tolerance parts for aerospace and energy sectors

ITAR registered (authorized to handle defense-related components)

Skilled with ISO 9001 and AS9102 inspection processes.

Every part is measured, documented, and verified. No assumptions. No shortcuts.

We GUARANTEE speed, precision and qualiTY

Single-part quotes returned within 12 hours; quote packages within 48 hours.

3-day prototype turnaround available after material sourcing.

No minimum order quantities required. One-off prototypes and scalable repeat production available.

Standard tolerances of ±0.003” with availability to hold down to ±0.0002” depending on material and geometry

All parts are reviewed and approved by the owner/operator for quality assurance.

Materials We Specialize In

Alloy & Tool Steels

Grades: 4140, 4340 (pre-hardened), A2, D2 (annealed), O1, S7

Applications: Ideal for molds, dies, and high-wear components

Capability: Extensive experience machining pre-hardened and annealed tool steels with tight tolerance control.

Titanium Alloys

Grades: Commercially Pure, 6Al-4V (Grade 5), 6Al-4V ELI

Applications: Aerospace, medical, and high-performance structural parts

Capability: Skilled in managing titanium's challenges including heat, rigidity, and surface integrity.

Stainless Steels

Grades: 17-4PH, 316L, 304

Applications: Corrosion-resistant and biocompatible parts

Capability: Experience across industries including medical, food-grade, and aerospace.

Aerospace Aluminum

Grades: 7075-T6, 6061, 2024

Applications: Lightweight structural components

Capability: High-speed machining with excellent surface finish on aerospace-grade alloys.

Engineering Plastics

Materials: PEEK, Ultem, Delrin, Torlon

Applications: High-performance, chemical-resistant, and insulative components

Capability: Precision machining with minimal thermal deformation and clean edge finishes.

Testimonials

Luke S.

"Please send invoice. Super happy with this part."

Confidential Client

“Responsive, fast, and accurate. Exactly what we needed to move forward with our prototype. Thanks Ben!”

Jordan R.

“Got everything done quicker than expected. Parts came out clean and exactly how we needed them."

Lets chat!

Location: Luling, Texas

Instagram

Mail

LinkedIn